India launched Bharat Taxi Service as First Cooperative-Owned Digital Mobility Platform

India launched Bharat Taxi Service as First Cooperative-Owned Digital Mobility Platform India places World’s First Live Commercial Order for Hyperloop-Based Cargo Logistics

India places World’s First Live Commercial Order for Hyperloop-Based Cargo Logistics How Weigh-in-Motion Systems Are Revolutionizing Freight Safety

How Weigh-in-Motion Systems Are Revolutionizing Freight Safety Women Powering India’s Electric Mobility Revolution

Women Powering India’s Electric Mobility Revolution Rail Chamber Launched to Strengthen India’s Global Railway Leadership

Rail Chamber Launched to Strengthen India’s Global Railway Leadership Wage and Hour Enforcement Under the Massachusetts Wage Act and Connecticut Labor Standards

Wage and Hour Enforcement Under the Massachusetts Wage Act and Connecticut Labor Standards MRT‑7: Manila’s Northern Metro Lifeline on the Horizon

MRT‑7: Manila’s Northern Metro Lifeline on the Horizon Delhi unveils ambitious Urban Mobility Vision: Luxury Metro Coaches, New Tunnels and Pod Taxi

Delhi unveils ambitious Urban Mobility Vision: Luxury Metro Coaches, New Tunnels and Pod Taxi Qatar approves Saudi Rail Link Agreement, Accelerating Gulf Railway Vision 2030

Qatar approves Saudi Rail Link Agreement, Accelerating Gulf Railway Vision 2030 UP Govt plans to introduce Water Metro services in Ayodhya, Varanasi & Prayagraj

UP Govt plans to introduce Water Metro services in Ayodhya, Varanasi & Prayagraj

How the Standard for Car and Truck Wheels Is Changing

Wheels are critical safety features that affect performance and reliability. New policies and technologies affect how transportation professionals approach them each decade. Changing standards mean comprehension and compliance are essential for following the law. Here is how drivers can stay ahead of the curve as the landscape shifts.

The Safety Changes in Car and Truck Wheels

Safety standards for car and truck wheels are getting stricter. In 2022, the National Highway Traffic Safety Administration (NHTSA) updated its standard reference test tire to amend the customer information regulation. Since its implementation, it has used the tire to evaluate treadwear, pavement surface friction and snow tires based on traction performance.

Another significant change came from the Society of Automotive Engineers (SAE). In 2021, it updated its performance requirements for passenger cars and light trucks to require new and replacement wheels to pass stricter impact and fatigue tests. Transportation officials should review these new standards, especially as the automotive industry welcomes electric vehicles (EVs).

Adjusting to the Era of EVs

EVs are annually increasing their market share and affecting how manufacturers approach wheel standards. Battery-operated cars are typically heavier due to their large battery packs, so the automotive industry has changed to accommodate them. Due to these bigger loads and torque ratings, the SAE’s 2021 testing changes apply to EV wheels.

From Tesla to Rivian, EV producers have made heavier wheels for strength and durability. Otherwise, the loads could cause cracks and failures. Manufacturers have focused on using lightweight materials like aluminum and magnesium alloys to reduce weight. In the last decade, the SAE has recommended using wheel covers and other permanently bonded surfaces to improve aerodynamic efficiency.

Implementing Advanced Wheel Materials

The automotive industry has moved toward advanced materials for EVs and gas-powered vehicles. Manufacturers have implemented aluminum alloy wheels because they are lightweight and resist corrosion. The metal has self-healing aluminum oxide that can protect itself when exposed to air. Drivers can find it on the Ford F-150 and other leading makes and models.

Besides the materials, wheels are getting advanced coatings and surface treatments. From powder coating to anodizing, new practices ensure components are more effective. Some treatments include automated and robotic polishing systems to deliver high-quality finishes and reduce labor. Experts say polishing wheels is a notable value-add service that extends longevity.

Getting Smarter With Automation

Automation is becoming more essential in polishing and other standards. Manufacturers leverage robotics and automated systems when casting, forging and finishing on the assembly line. Robots specialize in completing repetitive tasks with high precision levels, thus reducing labor costs. Automated systems can inspect wheels for imbalances, material defects and cracks. Smart sensors help drivers once they own the vehicles and start driving.

Modern cars and trucks include smart sensors to track individual components. OEMs like Maxion and Alcoa Wheels have introduced technologies to collect real-time load, pressure and temperature data. Drivers and transportation professionals can promptly respond to these issues with maintenance. Predicting failures before they occur is essential to reducing expenses.

Regulating the Aftermarket

Drivers may alter their machines to improve wheel performance or aesthetics. The aftermarket provides modification opportunities, though recent changes have included more regulations. Modern cars are heavier and more powerful, putting greater pressure on wheels. Another 2021 SAE recommendation included performance and certifying requirements for aftermarket wheels.

The updated guidelines refer drivers to SAE J2530. Aftermarket wheels must undergo rigorous testing, including dynamic cornering and radial fatigue. Real-world driving applications are vital to ensure wheels can handle daily use and heavy loads. Manufacturers follow the J2530 guidelines for wheel certification, which helps buyers and inspectors verify compliance. Stricter rules mean testing and traceability are more important for drivers.

The Environmental Shift in Wheel Standards

The rise of EVs correlates with manufacturers implementing sustainability policies. From Ford to Toyota, automakers are using recyclable materials in wheel manufacturing. Recyclability is another reason automotive companies have implemented aluminum — it is strong, lightweight and reusable without losing these properties.

Reducing wheel emissions starts on the assembly line, as new guidelines emphasize cleaner manufacturing processes. The European Union (EU) has proposed policies emphasizing recycled materials and easy dismantling once a car reaches the end of its life. Its suggested changes would reduce emissions and improve recovery rates for components like wheels. Similar policies are visible in California through its Air Resources Board.

Future Trends Shaping Truck and Wheel Standards

The automotive industry will continue emphasizing safety, technology and sustainability in its innovations. What should drivers and transportation professionals expect?

Artificial intelligence and other advanced technologies will impact policies at the SAE or government level. Drivers should anticipate trends like universal digital traceability, which embeds digital IDs to verify origins and compliance. Then, fleet management and recalls are easier to handle.

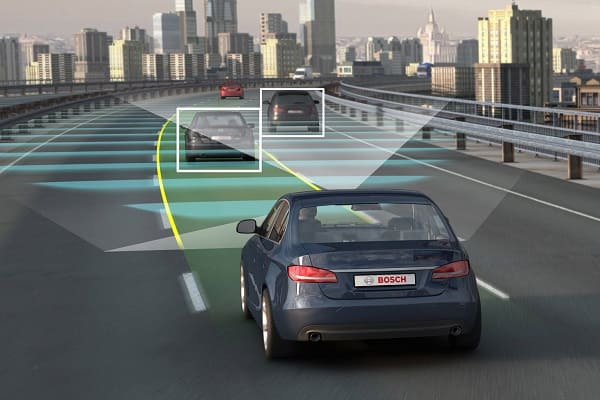

The automotive industry may have to change its wheel standards to accommodate autonomous vehicles. Self-driving cars rely on ultrasonic sensors, redundancy and fail-safe mechanisms, so industry regulations must address these components. Future changes may include new sensor hardware for mounting points or wheel materials for signal interference. Wheels are becoming part of the digital ecosystem, so cybersecurity integration may be necessary.

How Drivers Can Adhere to the Changes

Changing truck and car wheel standards means drivers must keep up with trends. The NHTSA, the Department of Transportation, and the International Organization for Standardization are reliable sources when reviewing safety and environmental standards. Vehicle owners should leverage new technologies like traceability features to ensure SAE or FMVSS compliance and verify the manufacturing origin.

Drivers can prepare for changing standards by staying ahead of the environmental curve. While a particular state or nation has yet to pass legislation, it could adopt policies later. Therefore, car and fleet owners should buy recyclable wheels and eco-friendly materials.

Once replacement is necessary, they can participate in recycling programs and reduce raw material emissions. Maintenance is also critical, as drivers should regularly check for cracks that could compromise compliance.

Keeping up With Changing Automotive Industry Standards

Car and truck wheel standards evolve annually, so drivers and transportation professionals face challenges and new opportunities. The new era includes stricter safety regulations, a rise in sustainability and EV growth. These elements have reshaped wheel design and manufacturing, helping vehicles last longer. Drivers should prioritize compliance with auto industry guidelines from the SAE or governing bodies.